The New Nomad 3 and Shapeoko Pro from Carbide 3D

I saw some exciting news on Twitter and Instagram this week. Carbide 3D is releasing updates to both their Nomad desktop CNC and their larger Shapeoko CNC router!

I am a happy owner of a Shapeoko XXL, and I’m always thinking about the Nomad 883. The Shapeoko serves me well for cutting wood and carbon fiber plates, but it isn’t a great machine if you want to cut metal. Every now and then I find myself wanting to design a small aluminum part for my drone frames, but I don’t want to deal with cutting aluminum on my giant Shapeoko XXL.

The updates to the Nomad have me even more interested in snagging one for my garage!

What’s the difference between the Nomad and the Shapeoko?

The Nomad and the Shapeoko XXL have similar price tags. The Nomad costs about $400 more, but the Shapeoko is a kit that you have to assemble yourself. You’re saving $400, but I bet you’ll spend nearly $400 of your time putting the Shapeoko XXL together.

The Nomad has a cutting area smaller than my Prusa MK3S 3D printer, while the Shapeoko XXL is so big, it wouldn’t even fit on my desk. Why on Earth would anyone buy a Nomad?!

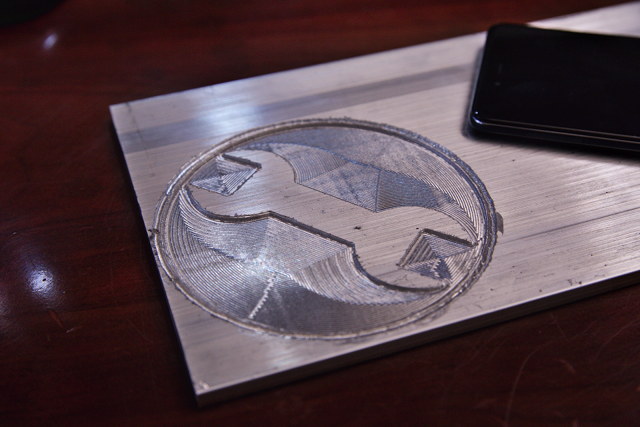

NOTE: This was my partially successful first attempt at cutting aluminum on my Shapeoko XXL.

The Nomad is tiny, but it is quite a rigid, powerful little machine. It has no trouble cutting aluminum and brass, and if you’re very careful, you can even use the Nomad to CNC yourself a nice steel knife!

The Shapeoko is optimized for cutting wood. It uses plastic v-wheels riding along aluminum rails, and each axis is driven by a belt. This is much less expensive than the lead screens and linear bearings of the Nomad, which is part of the reason why you can get a 33” by 33” cutting area on the Shapeoko XXL for about the same price as a Nomad.

The v-wheels and belts aren’t really a problem when cutting wood, but they sure do slow you down it you want to cut aluminum.

- Nomad 3 (And Something Else) at the Carbide 3D Blog

- Nomad CNC at Carbide 3D

- Shapeoko CNC at Carbide 3D

What’s new with the Nomad 3?

The most obvious difference is that the Nomad 3 is a much cooler-looking machine than its predecessor. The sides are cut from attractive bamboo, there are LED lights to help you see what’s going on while the machine is working, and there are even windows in the sides now.

The homing switches, lead screws, electronics, and spindle have all been upgraded. I’m not smart enough to tell you how much difference most of this will make, but I can tell you that I’d pay nearly the entire difference in price between the old Nomad 883 and the Nomad 3 just for the upgrade from the old 70-watt spindle to the new 150-watt spindle.

It sounds like they’re hoping to open up orders for the Nomad 3 on Oct 15. Carbide 3D is saying the price will be $2,800.

- Nomad 3 (And Something Else) at the Carbide 3D Blog

- Nomad CNC at Carbide 3D

What about the Shapeoko Pro?

The Shapeoko Pro has some pretty exciting upgrades. They’ve only announced the XXL version of the Shapeoko Pro, but they’re saying the two smaller sizes will be coming in the future.

As a Shapeoko XXL owner, I’m most excited about the Bitsetter and the integrated t-slot table. The Bitsetter is available as a $120 upgrade for my own Shapeoko XXL, and I have been tempted to add one to my machine for a while.

It looks like the t-slot table is extremely well thought out. Customizing my Shapeoko’s MDF table for work holding was a rather daunting task for a CNC newbie like myself, and I’m not convinced that I did a very good job. Having something like this shipped from the factory would have been awesome, and it also looks like it makes the machine more rigid.

We're thrilled to share with you the newest additions to our family, the Nomad 3 and Shapeoko Pro. This is the result of 7 years of experience building machines and your feedback to make the best desktop CNCs we've ever put out. More details here:https://t.co/F29Fdahkw0 pic.twitter.com/QmhgZqQ7K3

— Carbide3d (@carbide3d) September 30, 2020

Carbide 3D has also eliminated the v-wheels and switched to linear bearings on all three axes. This is a huge upgrade, but not one that I would notice much in my own work. I mostly cut carbon fiber plate and soft woods on my Shapeoko XXL. I’m not all that limited by the rigidity of the machine, but I have heard rumors that the v-wheels can be broken fairly easily if your machine crashes.

That said, if you need it, the Shapeoko Pro should be quite a bit more rigid than the Shapeoko 3 XXL. The y-axis isn’t just supported on each end any longer, so it won’t flex. The aluminum t-slot table looks quite a bit more rigid than the old MDF table, and the 15mm belts will be less prone to stretching than my Shapeoko’s 9mm belts.

Carbide 3D is saying the Shapeoko Pro will cost $2,800. I think that’s quite a fair price for such a nice upgrade over the $2,050 Shapeoko XXL.

- Nomad 3 (And Something Else) at the Carbide 3D Blog

- Shapeoko CNC at Carbide 3D

Is the old Shapeoko going away?

It is not going away. Thank goodness. I’m sure Carbide 3D knows there are plenty of folks like me that don’t need more machine than the current Shapeoko XXL. It is already a fantastic machine, and folks like me aren’t anywhere near hitting its limits.

The things I’d really like to be able to do with my Shapeoko 3 XXL wouldn’t work much better on the Shapeoko Pro. The rigidity upgrades on the Shapeoko Pro are nice, but I’d need something as rigid as the Nomad if I were planning on working with aluminum or brass on a regular basis.

The current generation Shapeoko is still a fantastic machine for most of us.

Conclusion

Carbide 3D has done a good job updating their line of CNC machines. I think it is neat that they now have two very different machines at the same price point. There’s the Nomad for folks that need a small footprint and need to be able to cut soft metals, and there’s the Shapeoko Pro for all the woodworkers out there.

What do you think? Are these worthy upgrades to the Shapeoko and Nomad lines? Are these updates something that would steer you towards buying a Carbide 3D CNC? Are you wishing your Shapeoko was a Shapeoko Pro, or are you happy with your existing machine? Let me know in the comments, or stop by the Butter, What?! Discord server to chat with me about it!

- Nomad 3 (And Something Else) at the Carbide 3D Blog

- Nomad CNC at Carbide 3D

- Shapeoko CNC at Carbide 3D

- I Bought a CNC Machine: I Have No Idea What I’m Doing