What's Pat Been Up To? December 2019

What happened?! I planned on doing one of these update blogs every month, but it sure looks like I completely forgot about doing this in November! Does that mean this update is going to be huge? Let’s find out!

These posts are mostly here for all you fine folks that are interesting in finding out about what I’ve been working on, but you don’t have the time to follow all my random tweets and blog posts throughout the month. I’ve been doing a lot of little things lately that aren’t exactly worthy of an entire blog post, so I’m going to try to mention that stuff as well.

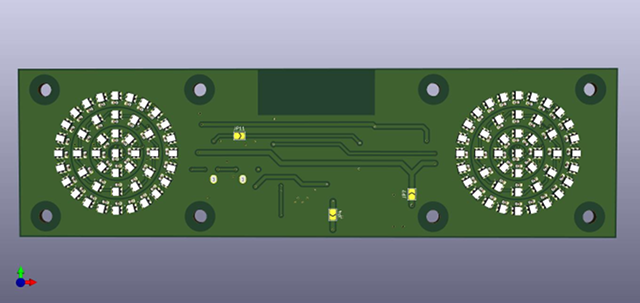

We’re getting close to ordering prototype OoberLights boards!

I’ve had schematics for the prototypes in hand since sometime around Thanksgiving. The holidays have been busy, and I’ve been working on getting a second set of eyeballs to look everything over before I order five or six prototypes.

If that goes well, I’ll be placing an order soon. If I don’t manage to get anyone to take a look at the schematics, I plan on ordering prototypes early in January. We might be posting some exciting stuff early next year!

I filmed my first real Cinewhoop flight!

I don’t know if it counts as a Cinewhoop if it doesn’t have prop guards, but last weekend, I strapped a GoPro to the top of my 4” Kestrel and recorded some slow, smooth chase footage. I managed to get about 90 seconds of awesome footage in a single take, I ran it through ReelSteady Go, and put a sound track underneath. I’m quite pleased with the results!

Brian was sent an electric skateboard to review. It is an Exway X1 Pro Riot skateboard. We spent the afternoon doing some range testing. I followed him on my electric bike, and we followed the bike trails at our local park. I didn’t think I had the range to keep up, so I parked while he made some laps around the lake.

I rode about 8 miles, while Brian got really close to 13 miles before running out of battery. He did a fantastic job.

Long-range testing on my Kestrel

Zoe FPV’s company, Outcast Droneworks, released an awesome little 3250 mAh 2-cell battery pack. My Kestrel’s are built to record HD footage while flying aggressive freestyle while running a 4-cell battery. As it just so happens, my Kestrels will happily fly on a 2-cell pack. They can’t do aggressive, twitchy freestyle, but it is the perfect setup for flying long range!

I haven’t planned out any sort of long-range mission yet, but I definitely have the rig for it now. I was able to just barely squeeze a set of gentle 4-inch biblade props on my 3” Kestrel. It is equipped with an HD video camera, GPS with return-to-home functionality, a long-range TBS Crossfire receiver, and a 1,000 mW video transmitter. With all that gear, it manages to squeeze in at 248 grams with the 2-cell 3250 mAh battery.

Here's the last of that flight, just to prove that it went 6 miles. She gets really wobbly under 3.2 volts or so. One of these days, I'll remember to work on tuning that out! pic.twitter.com/mOcxsA9Yz0

— Pat Regan (@patsheadcom) December 15, 2019

This is exciting, because in many parts of the world, it is illegal to fly a drone that weighs more than 250 grams. Here in the US, you don’t have to register your drone with the FAA if it weighs less than 250 grams.

I’ve only done four test flights with the 2-cell pack. They’re long flights, so they’re difficult to do back to back. My first flight lasted 19 minutes, but I didn’t have a GPS module to track distance.

You can read more details about this over on my blog, but I’ll give you the summary. All my flights with GPS have covered a little over 6 miles. That’s enough to fly about 3 miles away and return safely. That’s more than enough to get some cool footage flying down a mountain!

- 2s(7.4v) 3250mah Lithium-Ion High-Amperage Pack at Outcast Droneworks

I fell down!

I was doing a long-range test flight with my actual 4” Kestrel and the 2-cell battery. Four minutes in, I was flying past the sidewalk and didn’t see a fence until it was too late. My drone crashed, cracked its ND filter, and landed upside down. 8 volts didn’t provide enough power to flip the quad back over, so I had to walk over and get it.

Don’t click on the Twitter video unless you want to see me get hurt! I’m OK, so it is all right to laugh at me!

After the health problems I had last year, everyone was asking me all sorts of old man questions. “Did you pass out?” “Did you faint?” “Did you just wake up on the ground?”

Don't watch this if you don't want to see me hurt my face. A couple week ago, I didn't see the railing in the FPV feed, so my 4" Kestrel went down. The 2S battery didn't have the oomph to turtle, so I had to walk over.

— Pat Regan (@patsheadcom) December 7, 2019

After watching this, I'm surprised my neck doesn't hurt! pic.twitter.com/m0RDYe8rGO

Nope. I saw the whole thing. It is definitely an old-man problem, though. I have no excuse. There wasn’t any wet, slippery ground. We don’t really get ice here in Dallas, so that couldn’t be my excuse.

One second I was walking. The next second I was stumbling and trying not to fall. Then I was trying to keep my face from smashing into the edge of a 2’ high concrete wall.

Don’t worry. Most of my bleeding was only from my face. This happened about a month ago, and my face is mostly healed up. I bruised a knee, cut up some fingers, and hurt my right arm.

My Rancilio Silvia has its annual cleaning

I was late, though. I think I did this last over two years ago. When I replaced the gasket that time, I had to chop it up into a dozen pieces to get it out. It wasn’t rubbery anymore. It was hard and brittle.

I knew it was time to replace the gasket, because after last month’s injury, I couldn’t make espresso. It was just too hard to turn the portafilter far enough to get a seal. At the time, my right arm wasn’t really up to the task of replacing the gasket, either.

I ordered a gasket and screen kit anyway. Two weeks later, I was able to do the job without any real trouble. The gasket didn’t come out in one piece. It was almost out, but I wound up snapping it in half during the removal process.

All the brass pieces above the screen have been cleaned. The screen is replaced. The gasket is replaced. Everything is hunky dory.

I posted my NAS-building tips blog

Brian and I see the same questions pop up all the time. We’ve been seeing them for years. How many hard drives do I need to saturate Gigabit Ethernet? Is gigabit fast enough for streaming movies? What RAID level should I run?

I’m excited to finally have a place to point all these fine folks when they’re in need of an answer that doesn’t fit well in a tweet or comment.

I’m ready to cut a second 5” Falcon freestyle frame prototype

The first prototype held up surprisingly well. If I’m remembering correctly, I flew that first prototype frame from July until sometime in November before I finally broke an arm.

I’m not surprised that an arm broke. In fact, I’m surprised the arm lasted this long. I was in a rush. I knew the arms needed to be wider at the base than at the motor end, but I didn’t want to take the time to model them. I just wanted to see how they’d hold up at my chosen width of 13 mm.

I think I've done a good job at making the length of the wedge (a.k.a. the dog bone) parametric. Now I just have to figure out how long I'd like the bone to be! pic.twitter.com/W3M0E6XE7D

— Pat Regan (@patsheadcom) December 20, 2019

With hindsight, it is obvious that they wouldn’t be sturdy enough. The arms are barely three times wider than the hole for the M3 mounting hole, and there just isn’t enough material in that area.

I’ve tweaked a lot of things in the design, including the arms. I’m ready to cut a new frame. With any luck, I’ll get that done before the end of the year. I tried to do it yesterday, but I had a mishap. We’ll talk about that in the next section!

My Shapeoko XXL now has a dedicated laptop

I’ve been thinking about attaching a Raspberry Pi to my Shapeoko, but I still haven’t gotten that far. Until now, I’ve been running Universal G-Code Sender on my laptop, and hauling back and forth to the garage every time I do a cut.

I happened upon a spare solid-state SATA drive, so I put it in my old jumbo 18.4” laptop, loaded up Ubuntu and UGS, and I’ve given that laptop a permanent home on the desk next to my CNC machine.

I’m worried and possibly hoping that something isn’t right here. While cutting a duct for Tindie, my Shapeoko just stopped cutting. There were no errors, and I couldn’t send any commands with UGS until disconnecting and reconnecting.

I figured it was a fluke, but it happened again during the first 10 minutes of a 70-minute cutting job. I fumbled on the recovery, and drove the tool right through the sheet of carbon fiber.

I wasted a good bit of carbon on that mistake. Most of the holes were already drilled, and doing a full-depth cut during a rapid shifted the sheet of carbon fiber just enough to throw off my positioning.

The Duct Faces on Tindie have been upgraded

Way back in 2016, Brian built a DIY NAS using the Silverstone DS380B case. A lot of folks complained that there wasn’t enough airflow past the hard drives, so Brian designed a 3D-printed part to bolt onto the fans to help redirect the air.

I’ve been selling those on my Tindie store ever since, and they are easily my best-selling item. Even so, I hate selling them. It takes nearly three hours to print two orders’ worth of ducts, and it is less than 50 cents’ worth of plastic.

I’ve upgraded the ducts to carbon fiber plates with 3D-printed L-brackets. The carbon fiber is much sturdier than necessary, but it looks cool. The L-brackets are significantly beefier than Brian’s design, too, so these are quite an upgrade.

How did I do? pic.twitter.com/B4mH2Oy0TA

— Pat Regan (@patsheadcom) December 20, 2019

I can 3D-print enough L-brackets for six orders in the time it takes to print two sets of original duct faces. It takes less than two minutes to cut an order’s worth of carbon fiber. The material cost is up quite a bit. The time that I need to be involved has dropped a bit, but not as much as I want to.

I can’t just cut two dozen ducts out of a single 1mm-thick sheet of carbon fiber plate. The plate is too flexible. I might be able to cut four at a time without repositioning my hold downs. When I run out of 1mm stock, I might switch to 2mm plate. The thicker plates don’t cost much more, but I can probably queue up an entire sheet in a single cut.

Upgrades to my electronics workbench!

I bought a used variable power supply and a used Aeron chair from a friend a few weeks ago. I also dug out my little DSO Nano V3 oscilloscope to add to the setup. I have no idea what I’ll do with some of this stuff, but I’m excited about the upgrade!

I did a bit of rearranging to add new hardware to my miniquad repair bench. I made better room for the new adjustable PSU. I added my small oscilloscope and tiny logic analyzer. I also removed one multimeter, and added an Aeron chair. pic.twitter.com/pd8wfZolrb

— Pat Regan (@patsheadcom) December 4, 2019

The adjustable constant current power supply will come in handy. I’ve already wired up an XT-60 power lead. It will be handy for powering up quadcopters that I’m working on, and I can set the current extremely low to prevent blowing anything out in the event that I mess up my soldering work!

I’ve also upgraded my lighting. I found that nifty Wolverine gizmo at the Aldi. It has LED lights, AC power outlets with individual power switches, and a tool rack. I also added an IKEA arm lamp. It is becoming a rather hospitable place to work on miniquads!

I upgraded my vlog lighting, too!

I record all my vlogs at my desk using my DJI Osmo Pocket. It isn’t the most professional setup, but it works surprisingly well. I enjoy the way the Osmo Pocket is able to follow my face around while I’m talking. It makes me feel a little less static, and I almost feel like I have my own cameraman!

In general, I’m happier with the voice tracks recorded by my Osmo Pocket compared to my rather nice Zoom H1 mic. The Zoom is an infinitely better microphone, which means it picks up a lot more noise in my office. The fans in my computers, the hard drives in my server, and the air conditioning.

I've not yet vlogged with this setup. There is a 4-wing superbulb plugged into an IKEA arm lamp behind that diffuser. It might be too bright by about 25%. My little Osmo Pocket was overexposed at ISO 100 (minimum) and 1/60 shutter. I'll just push it to 1/80 shutter or so. pic.twitter.com/T2FOSLyXI4

— Pat Regan (@patsheadcom) December 4, 2019

I’ve been using these 60-watt LED light bulbs. They’re not 60-watt equivalent bulbs. These are actual 60-watt, 6000 lumen bulbs. I did my best to light myself indirectly. I stuck the bulb into a floor lamp that I already had behind my desk, and I tried to rig up a reflector near the ceiling. This was better than what I had, but it still wasn’t great.

I bought a $10 arm lamp at IKEA, and I clamped it to my monitor stand. Now I can point that giant bulb directly at my ugly mug, and I am able to jam a diffuser between the bulb and one of my monitors to make the lighting a bit less harsh.

I’m quite pleased with the results. I’m able to set the Osmo to ISO 100, which greatly reduces noise in the image. I’m also able to get close to a 180-degree shutter speed. A shutter of 1/60 would be 180 degrees, but that is a little overexposed, so I’m using a shutter speed of 1/80.

My face is lit better. The background is a little darker. I’m feeling significantly more professional. All I need now is some sort of accent or hair light!

- 60-watt 6000 Lumen LED Garage Bulb at Amazon

Conclusion

I am absolutely certain that there is more to include in this update, but it is already 1,000 words longer than I would have hoped, so I’m going to put a lid on it.

I am hopeful that I’ll have some interesting projects getting closer to completion next month.

What do you think? Have I been doing a good job? Does any of this stuff I’ve been up to need a more thorough explanation than has been given already, or is this stuff just totally uninteresting?! Let me know in the comments, or stop by the Butter, What?! Discord server to chat with me about it!